Capital projects rarely fail because of concrete or steel. More often, it’s the hidden scope gaps in electrical, instrumentation, and controls (EI&C) that derail timelines and budgets. That’s why the concept of Integration Management is gaining traction across the industry: projects need a dedicated role to close those gaps before they become problems in the field.

Whether you call it an Integration Manager or an Owner’s Engineer, the idea is the same. Modern facilities are too complex to leave system integration as an afterthought. It needs to be managed — proactively, consistently, and from the very beginning.

Where Projects Go Off Track

At Revere, where integration is our focus, we see the consequences of unclear scope and poor coordination play out all the time. The same themes come up again and again:

- Scope gaps from divided responsibilities. Separating automation from EI&C design leaves unseen gaps that usually surface late in the project.

- Under-budgeted OEM coordination. Owners often assume OEMs will handle their own integration, but in reality, no one takes full ownership of that scope unless it’s clearly assigned so that work usually falls through the cracks. The result is incompatible I/O maps, safety protocols that don’t align, and more.

- Vague scope or missing front-end definition. Too many projects launch without a proper FEED study, leading to incomplete P&IDs or sketchy load lists. Details like spare PLC slots, historian tag requirements, or network security needs only surface during commissioning — when they’re most expensive to fix. What could have been a simple one-hour adjustment early becomes days of rework in the field.

The impact of these gaps is felt in the field. One senior engineer at Revere recalled opening a set of network drawings only to realize they’d been copied straight from another job. “Half the hardware was obsolete,” he said. “The client finally told us, ignore the drawings and make your own. That kind of rework is exactly what Integration Management is meant to prevent.”

A project manager described a case where a client rejected Revere’s request to budget hours for OEM coordination. “They saw it as a duplicate effort,” he explained. “Months later, when the OEM packages wouldn’t communicate, it turned into a seven-figure change order.”

What Good Integration Management Looks Like

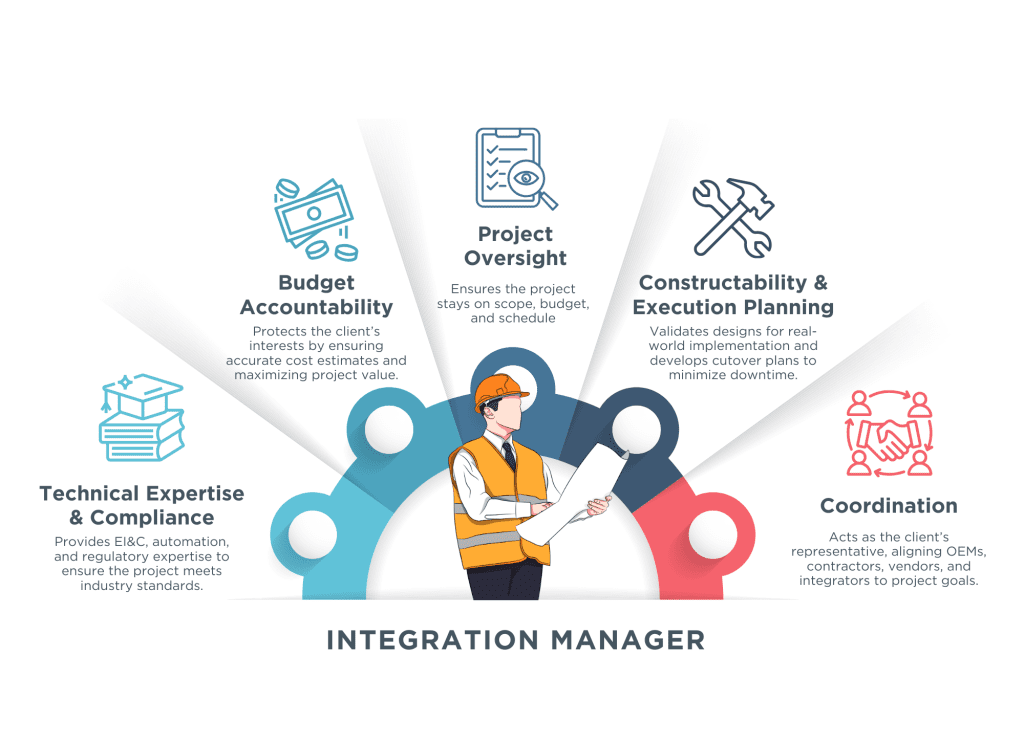

Integration Management is not a single deliverable, but a role that runs through the entire project lifecycle. In practice, it includes:

- Coordinating OEMs. Ensuring vendor packages align, not just in theory but in actual I/O maps and safety protocols.

- Front-end clarity. Leading FEED or FEL studies to define requirements to ±10% accuracy before major spending begins.

- Technical translation. Acting as a bridge between process teams, contractors, and controls vendors so design decisions reflect both real-world constraints and long-term operability.

- Installation management. Overseeing installation to confirm panels, cable routing, and network architectures are built as designed. This closes the gap between engineering intent and field execution.

- Change management. Surfacing scope adjustments early and addressing them before they spiral into costly field rework.

- Standardization. Bringing consistency to FAT documents, network architectures, safety zoning, and instrumentation specifications.

Lifecycle accountability. Delivering documentation, historian tags, and PLC logic detailed enough for operations teams to maintain years down the road.

One Revere project manager summed up why this role matters: “Most firms have deep benches in process or mechanical engineering, but very few controls specialists. Controls is all we do, so we catch issues early that others don’t.”

The Payoff

When projects embed an Integration Manager early, the benefits are tangible:

- Cleaner startups. With fewer handoff gaps and better-prepared commissioning plans, plants come online faster and with less troubleshooting.

- Lower risk of change orders. Scope is clarified up front, so owners avoid the surprise costs that come from mismatched equipment or incomplete design packages.

- Consistency across systems. Standardized hardware and documentation reduce complexity for operations and maintenance.

- Stronger vendor relationships. OEMs are supported, not left to guess how their package will connect to the rest of the plant.

- Long-term performance. Properly managed integration creates a control system foundation that’s easier to monitor, maintain, and optimize long after startup.

The growing use of the term Integration Manager is not a fad. It reflects a broader recognition that projects need a dedicated role to keep integration on track. Increasingly, that role also extends into Installation Management, ensuring what’s drawn on paper is exactly what gets built in the field.

For decades, Revere has filled this function under different names. What’s new is that more owners are now naming it, budgeting for it, and expecting it, and the earlier this role is embedded, the more value it delivers in saved time, reduced risk, and smoother startups.