As part of the SJE family of companies, we’re proud to shine a spotlight on one of our own:Horlick, a Massachusetts-based manufacturer and engineering firm whose work has been trusted across industries for nearly a century. Founded in 1936 in Boston by two brothers, Horlick started out supplying electrical equipment and switchgear. They became known for their motor generator sets — specialized systems for converting electrical frequency — and over the decades expanded into custom control panel manufacturing.

In 1969, Horlick was even recognized by the Associated Industries of Massachusetts for their contribution to the Apollo II moon landing, an early milestone that highlighted the company’s technical expertise in high-stakes applications.

Today, Horlick’s capabilities stretch from commercial bakery and food production lines to aerospace testing facilities, advanced manufacturing plants, and critical defense applications. In their words, they work on projects “from satellites to sneakers”, a nod to the range of industries they serve, from aerospace to a recent project with a popular sneakers brand. As part of the SJE family, Horlick strengthens our collective ability to serve sectors where their name is already well known, particularly in food and baking automation and in the specialized field of motor generator set design and manufacturing for frequency conversion.

Core Industries and Applications

Food / Baking

In New England and beyond, Horlick panels power the ovens and production lines that support some of the most well-known names in baking and food production. Horlick builds tunnel oven controls and food automation systems for commercial bakeries and food plants across the region, working closely with OEMs to meet tight production schedules, handle frequent product changeovers, and comply with food safety standards.

As part of the SJE family, Horlick’s baking industry expertise expands our collective ability to serve food manufacturers nationwide.

Defense

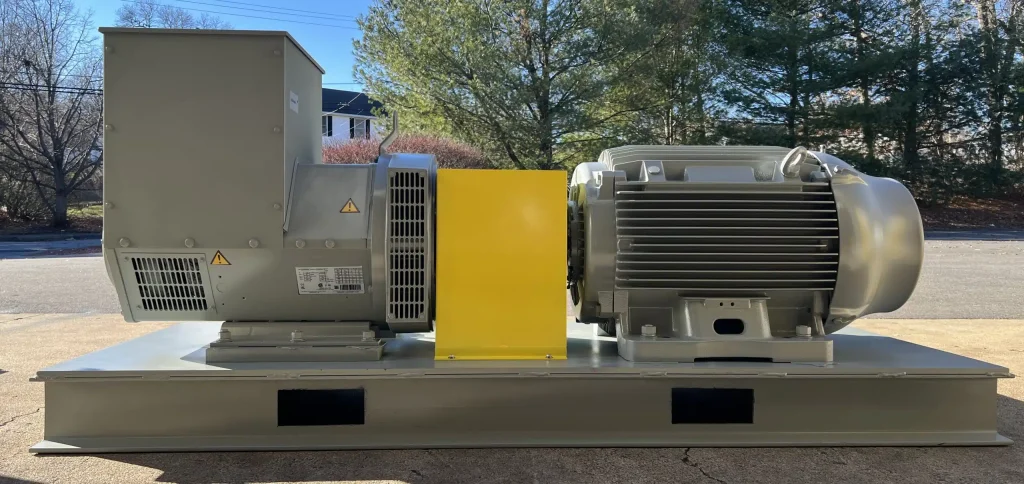

Horlick is also recognized as a sole-source supplier for many motor generator set (MG set) applications in national defense. These systems perform frequency conversion — such as converting 60 Hz to 400 Hz for aircraft ground support or adapting 50 Hz foreign-built equipment for U.S. facilities — while holding tight voltage and frequency tolerances under varying loads.

Designed for decades of continuous service, MG sets may operate in controlled rooms or outdoor enclosures exposed to extreme conditions. As Mark Caldwell, plant manager at Horlick, notes, “We are often one of two companies in the world able to build to these specifications,” with their combination of generator and custom control panel expertise.

For customers needing temporary frequency conversion, Horlick also offers motor generator set rentals, with each unit fully tested and ready to ship.

Factory Automation

From robotics integration to fully automated production lines, Horlick provides factory automation controls that boost efficiency and consistency. Their team can handle everything fromSCADA programming andremote monitoring integration to final panel build, giving OEMs a turnkey solution without needing to expand their in-house control capabilities.

Materials

Horlick builds control panels for physical vapor deposition (PVD) systems and other material processing automation equipment, where precise control over temperature, vacuum, and process sequencing is critical. These panels often integrate with SCADA programming or remote monitoring systems, allowing operators to track and adjust process parameters in real time. Horlick’s engineers work closely with OEMs to design control systems that not only meet tight performance tolerances but also fit seamlessly into complex, high-value manufacturing environments.

Compressors

For OEMs producing specialized industrial compressors, whether for air, gas, or process applications, Horlick delivers custom control systems that manage motor operation, load sequencing, and safety interlocks. Designs may incorporate variable frequency drives (VFDs) for energy efficiency, automated fault diagnostics to minimize downtime, and hazardous location compliance when required. Built for durability and ease of maintenance, these compressor control panels are tailored to the end application’s exact performance and environmental requirements.

What Sets Horlick Apart

Workmanship Standards

The consistency customers see when they open a Horlick panel starts long before it leaves the shop floor. The company’s workmanship standard, developed over decades, defines exactly how each panel is built, down to the smallest detail, and it’s the foundation for Horlick’s reputation.

“My production manager, who’s probably the best wireman east of the Mississippi, has been with us for 25 years,” says Mark Caldwell. “He created the workmanship standards, and that’s what we hang our hat on every day. That’s how we train our employees.”

When describing the level of detail built into this standard, Caldwell points to their approach to wire terminations as an example. Every exposed copper conductor is finished with a ferrule, a small metal sleeve crimped on before the wire is secured in a terminal. This takes extra time and adds cost, but as Caldwell explains, “At the end of the day, we think it’s a better electrical joint when it’s done that way, and we bake that into the price of our panels.”

Even the label orientation is deliberate. Labels are applied to match the way most technicians naturally tilt their head when working — typically to the left — so the text is easy to read at a glance. “If you open up one of our panels, every single wire label reads the same way,” Caldwell says. Multiplied across hundreds of connections, that consistency saves significant time in the field.

These details, combined with certified compliance to UL 508A, UL 698A, and UL NNNY standards for control panels in both general purpose and hazardous locations, ensure every Horlick build meets strict quality, safety, and usability expectations. Horlick also maintains multiple certified UL Manufacturer’s Technical Representatives (MTRs) on staff to oversee compliance and quality. It’s the same philosophy that drives theRevere Standard for panel building; consistency, reliability, and craftsmanship in every unit.

Design-to-Build Flexibility

Horlick can start with a fully developed drawing package or nothing more than a concept sketched on the back of a napkin. That flexibility allows them to meet customers where they are, whether the job calls for build-to-print precision or full engineering design from scratch.

Focused Expertise, Expanded Reach

Horlick’s philosophy is straightforward: customers should concentrate on their own core business, and let Horlick handle the controls.

Caldwell recalls working with a thermal vacuum equipment manufacturer, a company whose chambers simulate the extreme conditions of outer space. Before partnering with Horlick, their engineers were spending valuable time building control panels in-house. “Those guys shouldn’t be tied up building panels,” Caldwell says. “They should be focusing on what they do best. Panels aren’t their core competency — they’re ours. You focus on what you do best. Let us do what we do best.”

As part of the SJE family, that capability goes even further. Horlick’s designs, engineering oversight, and workmanship standards can now be supported by a 15-plant manufacturing network when needed. If their Massachusetts facility reaches capacity, production can be shifted to another SJE site, but the customer still works with the same Horlick engineer, and the finished panel still reflects the same build quality.

This combination of specialized focus and expanded capacity means customers get the benefits of working with a niche expert, backed by the scalability and resources of a national manufacturing network. No matter where it’s built, the final products will be indistinguishable in quality, function, and appearance.

Looking Ahead

This year, Horlick will attend a major international baking industry trade show, IBIE in Las Vegas on September 14-17; their first presence at an industry event in two decades. They’ll use the opportunity to strengthen OEM relationships, explore co-marketing opportunities, and build connections in this industry.

As they approach 90 years in business, Horlick’s commitment remains the same: precision engineering, meticulous workmanship, and the confidence that comes from knowing your control systems are in expert hands.

Whether it’s food automation, defense control systems, factory automation, or motor generator set applications, Horlick delivers the expertise and consistency OEMs rely on — now backed by the capacity and reach of the SJE network.

Learn more about Horlick and the SJE family of engineered control solutions.