How Cloud-Based Monitoring Helped a Florida Utility Pinpoint the Source of Sewer Overflows

A Familiar Problem: Manual Monitoring and Reactive Maintenance

A Florida utility operates a network of wastewater pumping stations that are central to public health and environmental protection. Like many municipalities, this utility traditionally relied on manual processes to manage these assets. Field personnel traveled to each site daily to record pump runtimes from hourmeters and respond to alarms—often only after issues had already escalated.

The most urgent concern centered on one site in particular, which had experienced intermittent overflows with no clearly identifiable cause. Suspecting stormwater infiltration, operators began visiting the site daily to log pump data by hand and estimate flow—an approach that consumed valuable staff time, but provided limited insight. The city needed a better way to monitor conditions, diagnose the issue, and prevent future incidents. City leaders also recognized an opportunity to modernize wastewater operations systemwide. To improve visibility into data across their stations and streamline maintenance, they partnered with Mader Electric (a PRIMEX Engineered Representative) and SJE to evaluate the possibility of a remote monitoring solution.

At the time, all of the city’s pump stations were already in service, meaning any new technology would need to be integrated into existing infrastructure without interrupting operations. This introduced several technical and organizational challenges:

- Space limitations in control panels made it difficult to install new hardware like remote terminal units (RTUs).

- Power supply constraints required careful electrical modifications to support added monitoring devices.

- Older motor starters didn’t support native data collection, so auxiliary contacts had to be added to capture pump run status and detect overloads.

- A cultural shift was required in order for operators to transition from manual logs to digital dashboards and automated alarms—a major change in workflow.

The Solution: Cloud-Based Monitoring with Pump Watch

After selecting the high-priority station as the ideal pilot location, SJE and Mader Electric worked with the city to install a deployment of Pump Watch—a cellular RTU with a cloud-based dashboard designed for wastewater applications, at that site. The system was installed for a six-month trial, giving operators access to runtime data, flow trends, and alarm-based notifications from a secure remote platform.

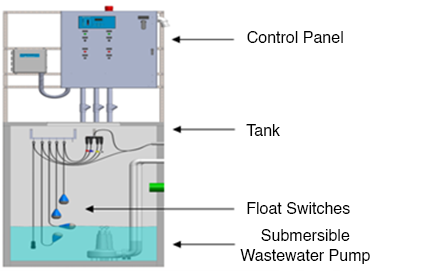

As shown in Figure 1, the pilot site featured two 10 HP sewage pumps installed in a 20-foot-deep underground wet well. Pump operation was controlled by four float switches in a cycle-based ON/OFF configuration. Each pump could handle up to 300 gallons per minute (GPM), with the station averaging 60,000 gallons per day. The control panel used across-the-line (direct-on-line, or DOL) motor starters—standard in legacy systems but not built for digital monitoring or data logging.

Pump Watch was configured as a monitoring-only solution, with no remote control capability aside from a relay used to silence the onsite audible alarm. The system provided:

- Scheduled Data Logging: Every 10 minutes, the RTU transmitted operational data to the cloud, capturing trends in flow, runtime, and power conditions.

- Event-Based Alerts: Operators received real-time alarms for issues such as high water levels, motor overloads, or phase loss.

- Remote Access: Staff could view live and historical data from any internet-connected device—eliminating the need for daily site visits.

- Analog and Digital Inputs: The RTU captured detailed signals, including:

- Pump run status and overload trips (via motor starters)

- Voltage/phase conditions (via phase monitor)

- Wet well level and high-level conditions (via float switches and level transducers)

- Motor current (to detect high draw or dry run scenarios)

Immediate Impact: Uncovering the Source of Overflows

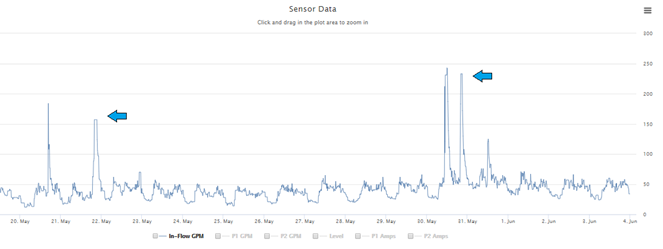

The benefits of Pump Watch were quickly realized. With access to real-time and historical data, the team was able to correlate inflow spikes (shown in Figure 2) at the station with heavy rain events.

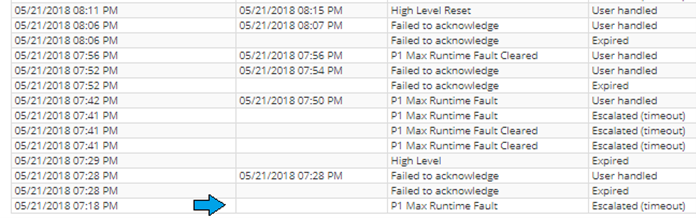

Using timestamped data on pump runtimes and tank levels (see Figure 3), they traced the issue to open cleanouts at a nearby gas station, which were allowing stormwater runoff to enter the sanitary system. Once the infiltration source was identified and corrected, the recurring overflow issue was resolved.

With Pump Watch in place, the team no longer needed to conduct daily site visits. Instead, they received alerts when needed and reviewed trends remotely, allowing them to:

- Quickly identify abnormal conditions

- Shift maintenance to condition-based scheduling

- Reduce labor demands and emergency response time

- Improve overall operational efficiency

“This utility’s operations team was proactive, open to innovation, and committed to improving how they manage their wastewater infrastructure. By embracing remote monitoring, they didn’t just solve an operational challenge—they set a new standard for how municipalities can leverage cellular monitoring and cloud-based reporting to boost reliability, improve efficiency, and reduce costly downtime. It’s been a great example of what’s possible when the right tools and the right team come together.”

— Julian Atchia, Vice President of Research & Development, SJE

Following the success of the pilot site evaluation, the city made the decision to expand the Pump Watch system across all of its wastewater pumping stations. Because the RTUs were compact, adaptable, and didn’t require major panel upgrades, the team was able to standardize monitoring across its infrastructure quickly and cost-effectively. This is helping the city lay the foundation for data-driven infrastructure management—ensuring they stay ahead of problems, rather than reacting to them after the fact.