With new safety standards hitting the paper industry, some friction while getting up to compliance is unavoidable, but Revere has developed some proven methods for making the transition as smooth as possible. In this article, we take a closer look at the modernization of one major US paper mill’s winder deck and how the approach taken can be applied across the industry.

Changing Safety Mandates

Across the paper manufacturing industry, modern machine safeguarding is no longer a “nice to have.” Standards like OSHA compliance, ISO 13849, and TÜV safety requirements make it clear: if you touch legacy equipment — even during a minor upgrade — you must bring the entire system up to modern industrial safety compliance. For paper mills, where equipment may date back to the 1970s, that can be a tall order.At one mill operated by a major U.S. paper producer, Revere Control Systems was brought in to design and deliver a safety integration project focused on the winder deck, a high-risk zone where massive paper rolls are cut, labeled, and conveyed at speed. The goal was to engineer a safety system that would protect mill employees without stalling production.

Facing Risk at the Winder Deck

The winder deck is one of the most dangerous areas in a paper mill. Rolls weighing thousands of pounds move quickly across conveyors, often requiring human intervention for labeling, taping, or repositioning. Historically, these areas were wide open — operators would step in between rolls or onto conveyors during operation. Crush hazards, trip hazards, poor visibility, and manual overrides turn the winder deck into a high-risk zone where one misstep could mean serious injury. Even so, many facilities hesitate to modernize, fearing that safety upgrades will impact the bottom line. Avoiding outages and maximizing production often take priority.

There’s no sugarcoating it — roll handling safety systems and machine safeguarding processes inherently introduce friction. Sliding gates require stops and resets. Fully automated sequences are efficient when they work perfectly, but even a single sensor fault can bring production to a halt.The key isn’t to pretend those tradeoffs don’t exist, it’s to design around them. That’s where thoughtful planning and process understanding come in. In this project, the Revere team focused on balancing safety with operational demands, building in diagnostics, streamlining access procedures, and minimizing delays during resets and troubleshooting.

As one senior control system specialist at Revere put it:

“You could make the mill perfectly safe by telling everyone to stay home. But that doesn’t work. You need people here, working safely. That’s what we design for.”

This project didn’t eliminate every delay — no system can. But it was engineered to reduce disruption, streamline resets, and build confidence that “safe” doesn’t have to mean “slow.”

Revere’s Approach: Safety By Design

Comprehensive Risk Assessment and Hazard Analysis

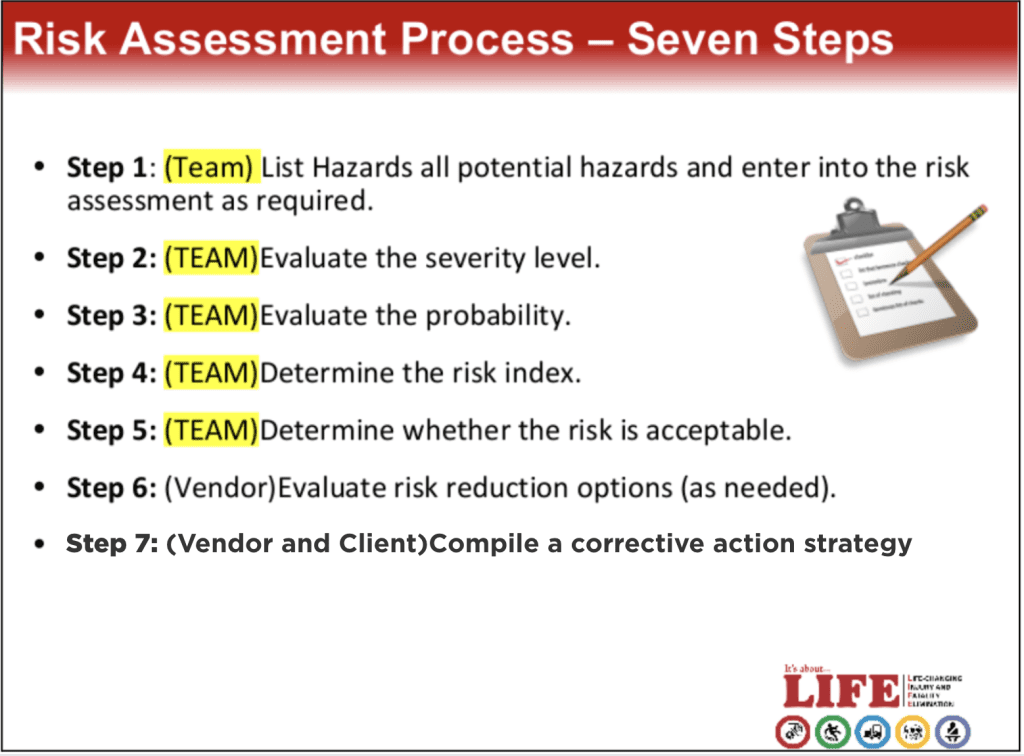

Revere began with a collaborative risk assessment and hazard analysis, walking the line with the mill’s operators, safety team, and engineering leads. Every hazard — from mechanical to environmental — was mapped, scored, and addressed, resulting in a shared, documented scope of work that aligned compliance needs with real-world operations.

Rather than relying on a predefined scope, the team worked with the client to define safety and operational needs based on firsthand observation and risk prioritization.

After the full risk assessment, several high-priority areas for improvement were pinpointed:

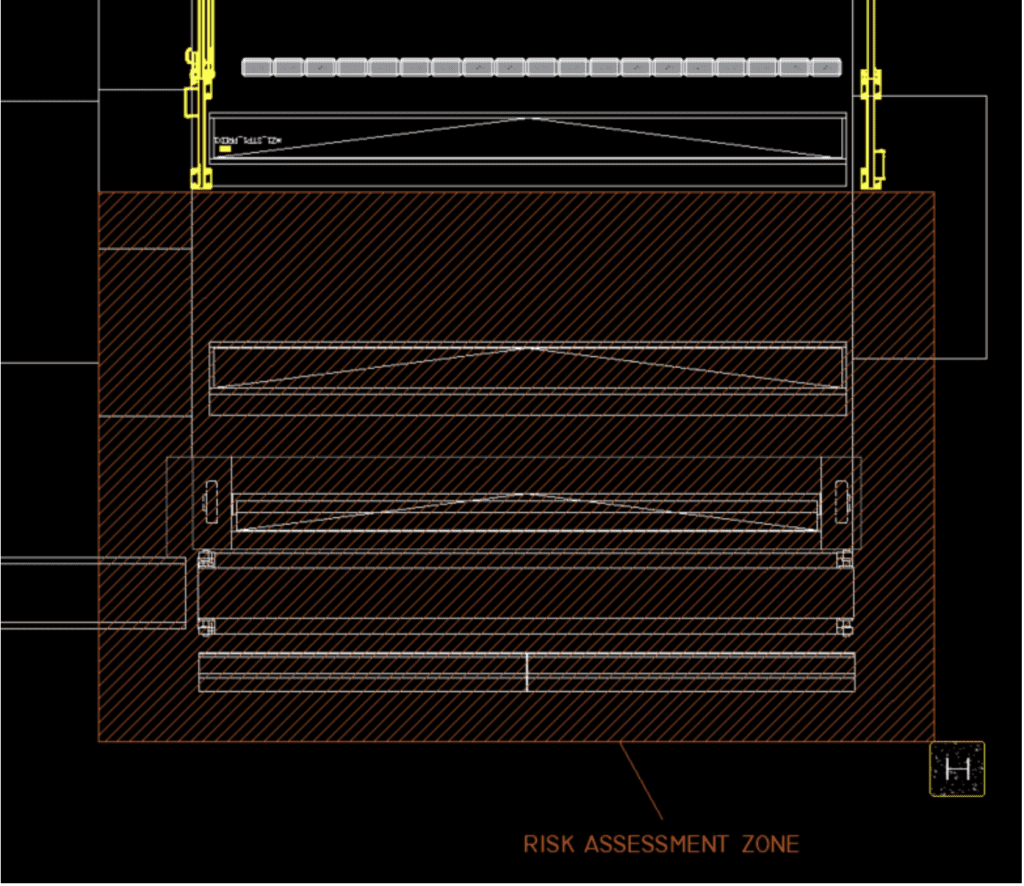

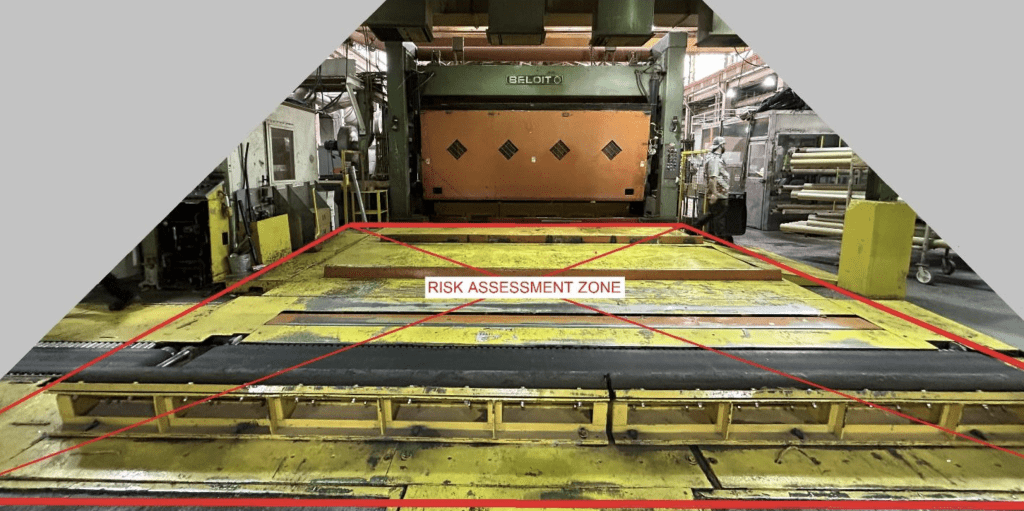

- Open-access hazard zones where massive rolls moved freely across conveyors without restriction, introducing crush and trip hazards (seen in Figures 1 and 2).

- Manual entry points where operators would routinely step into active conveyor areas without interlocks or automatic shutdowns.

- Outdated control panels and inconsistent diagnostics, leaving operators with little information when the system failed to restart.

- Unprotected roll egress paths, where forklifts extracted rolls during outages without defined safety boundaries.

- Environmental hazards like heat, poor visibility, and noise — all of which added risk during manual intervention.

From this assessment, Revere helped develop mitigation strategies that preserved uptime while delivering the necessary level of protection:

- Request-to-enter gates that safely shut down only targeted systems

- Smart fencing and scanner layouts that preserved visibility and workflow

- A “tennis fence” bypass zone for safe roll removal during outages

- Improved HMI interfaces with clear alarms and diagnostics

Turnkey Winder Deck Safety Automation

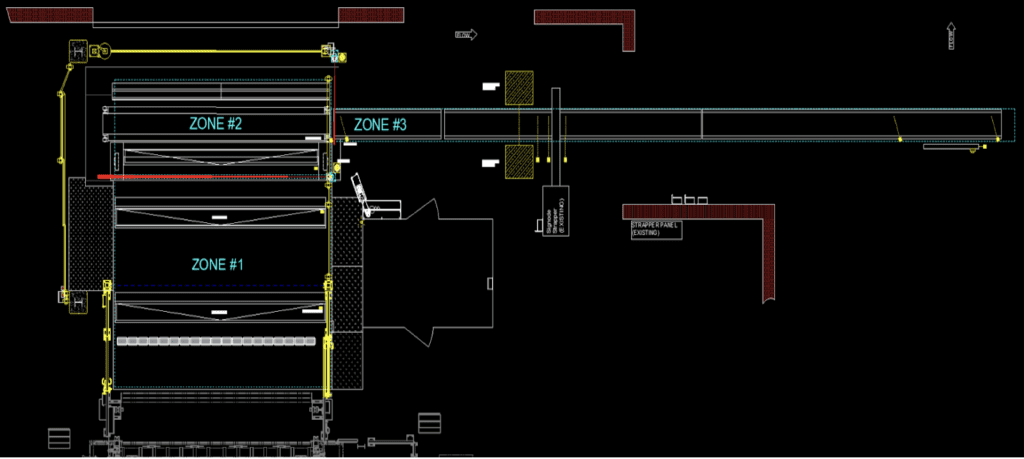

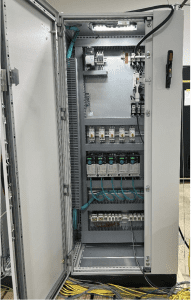

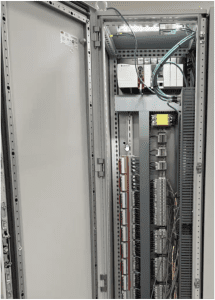

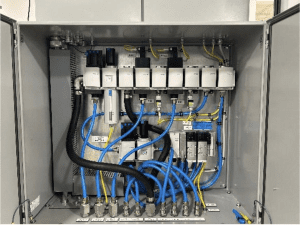

With scope agreed upon, Revere delivered a full turnkey automation project (shown in Zones #1 and #2 in Figure 3), covering demolition, controls engineering, installation, and validation. Key components included:

- Sliding gate fencing with request-to-enter interlocks

- A tennis fence access zone to enable safe roll removal during conveyor outages

- Laser scanners, safety PLCs, and HMI panels with diagnostics and alarms

- Fully integrated photo eyes, proxy sensors, and motor drive systems

- A clean, documented automation panel build

Planning for Future Safety Expansion

The team also addressed an area of the downstream roll transport conveyor area, even though it wasn’t part of the official safety scope (shown as Zone #3 in Figure 4). That zone remained open access at the mill’s request, but the drive systems and panels are standardized and prewired to support an eventual equipment safety upgrade in the future with minimal additional outage time.

Pre-Installation Testing and Documentation

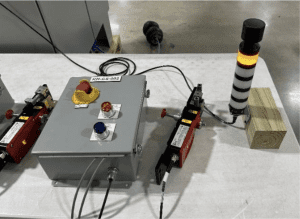

A key part of this project was the thorough testing process completed before installation. With mill outage planning always a high-stakes variable in the paper industry, reducing field surprises was essential. Before any equipment left the shop, it underwent a full Factory Acceptance Test (FAT) in Revere’s dedicated industrial panel shop:

- Energizing all safety PLCs, interlocks, and automation logic

- Testing laser safety sensors, air-actuated systems, and alarms

- Verifying functionality for each photo eye, proximity switch, and gate entry box

- Inflating actual airbags to validate physical responses

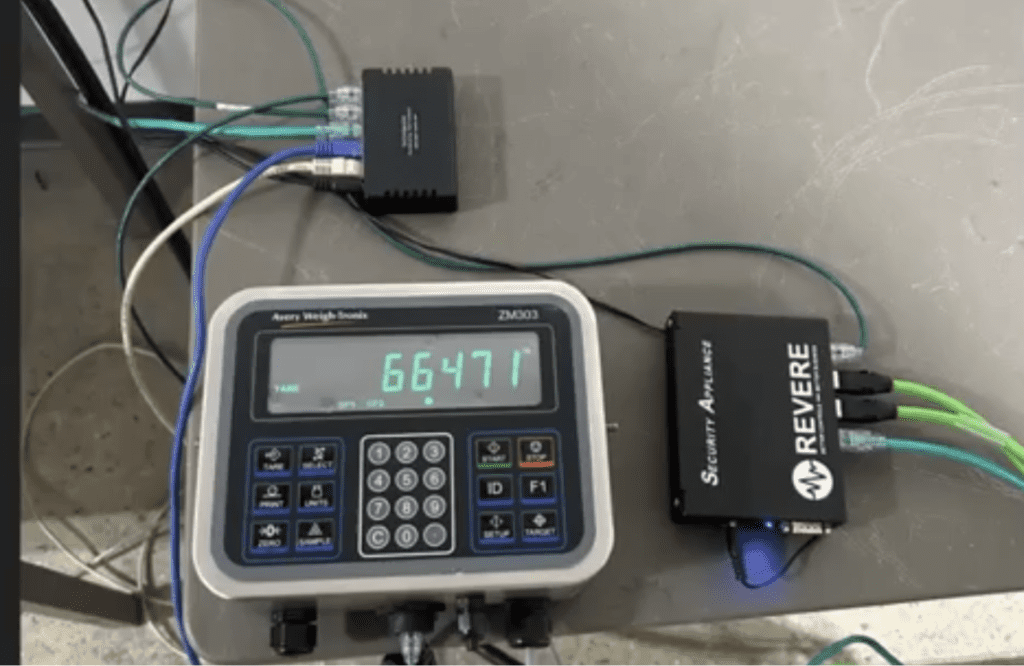

To ensure accurate integration, the team even sourced an Avery scale controller — the exact model used at the client’s site — from eBay. By simulating its behavior during FAT, they were able to preempt compatibility issues before arriving at the mill.

“We’d rather spend $200 now than lose a day during an outage,” one engineer noted regarding the scale controller purchase.

As part of the validation process, the team also confirmed that system components met the required safety integrity level — applying SIL 1, SIL 2, or SIL 3 standards as appropriate based on ISO 13849 risk assessments.

All results were logged in a formal safety validation checklist, with engineers signing off on performance and locking the safety PLC to preserve code integrity. Final as-built documentation was delivered to the client with updated, field-verified drawings, providing clarity long after the outage window closed.

Final Result: Safer, Smarter Operations

With the system live, the mill now benefits from a paper mill safety upgrade that meets current codes, improves operator confidence, and positions the facility for long-term success with streamlined diagnostics and responsive HMI interfaces.

Beyond the results of this particular project, the success of this approach has broader relevance for similar safety upgrades across the paper industry. No two mills are the same, so no two safety upgrades should be. The work done in advance of the rollout — from detailed risk assessments to real-world walkdowns with site teams — meant that this mill’s operations weren’t being forced into a one-size-fits-all solution. That’s where many projects go sideways: when a standardized design gets dropped into a complex, production-critical environment without regard for how things actually run on the floor.

This project also points to another important truth: you don’t have to tackle everything at once. Safety upgrades can feel overwhelming, especially in aging facilities with complex production demands. But as this project showed, taking a phased approach — tackling the highest-risk areas first and building in support for future expansion — can make the path forward more manageable.

By focusing on actual plant conditions, not generic checklists, and by validating everything before the outage window opened, Revere helped ensure a smooth transition without unnecessary disruption for this mill. For other facilities facing similar mandates, this project offers a proven, practical framework for moving forward with confidence.